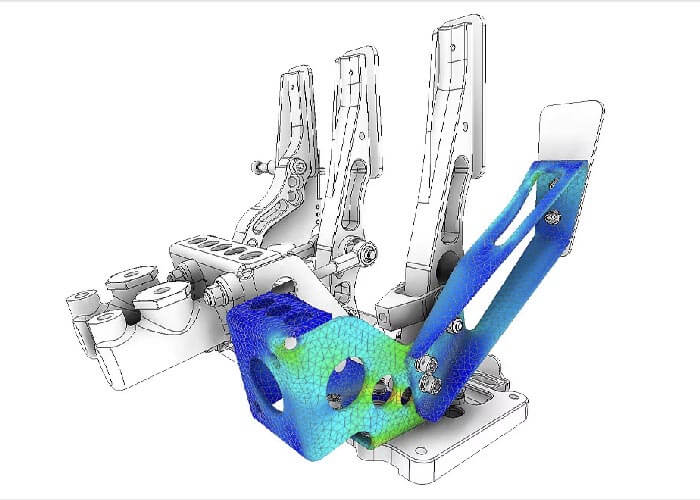

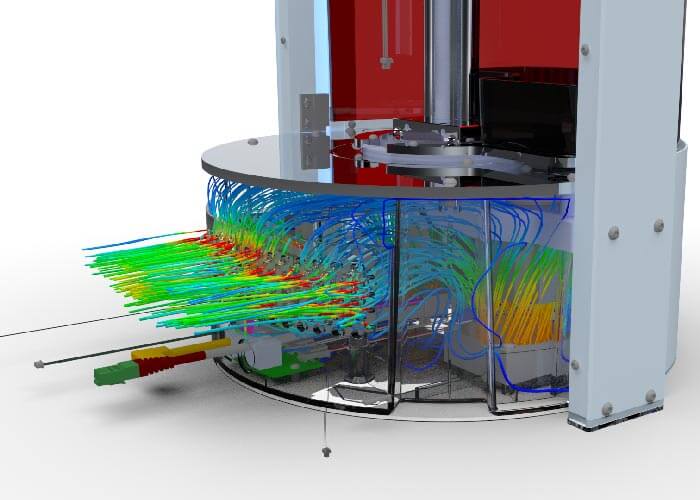

The Inventor Nastran software is an advanced finite element analysis tool (FEA) fully embedded in Inventor that makes it possible to perform multiple types of analysis such as linear and nonlinear fatigue, dynamic analyses, and heat transfer. Inventor Nastran offers a high level simulation technology in a workflow embedded in CAD to turn out excellent products.

The Inventor Nastran software is an advanced finite element analysis tool (FEA) fully embedded in Inventor that makes it possible to perform multiple types of analysis such as linear and nonlinear fatigue, dynamic analyses, and heat transfer. Inventor Nastran offers a high level simulation technology in a workflow embedded in CAD to turn out excellent products.

The benefits that FEA technology integrated into Inventor CAD can offer in product design and development are enormous. In fact, advanced analysis makes it possible to verify how well designs work under real-world conditions.

It is an indispensable step to optimize the market performance of products, to achieve maximum performance certainty and to ensure an ‘optimal production phase. All this translates not only into innovation, lower costs and reduction of errors and criticalities, but into absolute product quality.

The reason why the use of FEA technology proves to be an indispensable choice for the company is due to the advanced characteristics of the simulation: through a series of indexed parameters, recorded and traceable in reports, the company can prove, even to third parties, that it takes all possible precautions to ensure that the design is transformed into undisputed product quality every time.

With its integrated workflow, Inventor Nastran simplifies processes, highlights compatibility issues, while providing an industry-recognized, professional-level FEA platform. Ease of use, integration and system associativity crown a software that pushes forward the bar of industrial utopia: creating perfection.

Nastran is easy to use: it eliminates the need to use other simulation technologies for different platforms by integrating directly into Inventor.

By reducing the learning curve and maintaining productivity, Nastran eliminates compatibility issues generated by importing CAD models into different FEA platforms.

Part geometry data are accessible directly from the CAD system and offer true associativity of geometries. Thus, it is possible to easily modify the model without duplicating validation work. And you can explore hypothetical scenarios immediately, thanks to the full associativity of FEA and CAD data.

Inventor Nastran is an FEA problem-solver for multiple uses, known mainly for its precision in linear and non-linear stress analysis, and in the heat transfer of mechanical structures and components.

Material data are critical to the accuracy of simulation during design. Simulation of materials such as metal, composites, rubber and plastics allows users to more accurately predict a product’s performance or even its possible failure. Inventor Nastran supports a wide range of materials, thanks to which it is possible to learn more about the behavior of products in the real world.

Inventor Nastran basically makes it possible to anticipate the mechanical performance of components subjected to loads, predict possible errors/weaknesses, manage safety factors, develop alternative designs or materials, perform checks in critical areas and generate reports of the analyses performed.

With digital simulation, companies are able to accurately and quickly model and analyze product performance characteristics while reducing physical prototypes. With Inventor Nastran you can run simulations in-house instead of outsourcing them.

Inventor Nastran is an advanced simulation software: through the finite element method (FEM) analysis integrated in CAD, it allows the mechanical and structural behaviour of a design to be verified at an early stage.

How much does Inventor Nastran cost?

Inventor Nastran is available through the Product Design Manufacturing Collection.

You can subscribe to Inventor Nastran on the QS Infor website:

Behavioral predictions make it possible to proceed with confidence before even thinking about the construction of a possible prototype, resulting in significant cost savings. The module allows a multiplicity of analyses to come to life: static simulations with mechanical verifications, handling various types of nonlinearities, materials, dynamic analyses such as vibration, fatigue, heat transfer, peak loads.

Directly oriented towards specific application processes that, like mechanical engineering, require familiarity with dedicated libraries and applications, the courses organised by QS Infor are structured according to the customer’s needs and objectives, on an individual or group basis, at the customer’s company or at the QS Infor site.

We are always just a click or phone call away

Only what you need, exactly for you

If need be, we lend a hand

Piazza Meuccio Ruini, 29/A

43126 Parma

+39 0521 944592

Via Torino, 1/C – Negrar (Arbizzano)

37024 Verona

+39 045 7112089

Via Verdi, 6

40026 Imola

+39 0542 1886513

© 2021 - QS Infor S.r.l. unico socio - Piazza Meuccio Ruini, 29/A - 43126 Parma | Tel. 0521 944592 | Email: info@qsinfor.it and PEC:pec@pec.qsinfor.it

C.F. and P.IVA 02270320340 | Cap. soc. € 10.000,00 int. Vers. | E.A.I. Parma 224432 | Registered with the Chamber of Commerce, Industry, Agriculture and Artisanship of Parma 02270320340

Privacy Policy | Cookie Policy | Terms and Conditions